Companies in the metallurgical sector need solutions to control various quality factors and optimize processes. This includes the homogeneous production of ingots, the control of the level in the furnaces and storage tanks of the aluminium injection presses, and the homogeneous production of steel bars and tubes.

One of our clients needed to ensure that all ingots had the same amount of aluminium in the moulds. This was achieved by monitoring the fill level of the ingots online with one of our sensors and coordinating the level of advance of the belt. Thanks to this solution, manufacturing quality was ensured, production was optimised and reprocessing was reduced by having to re-melt ingots that did not meet specifications.

Another customer implemented a level control system for the storage tank in the manufacture of aluminium injection presses to inform the operator of the transport bucket when the machine should be filled.

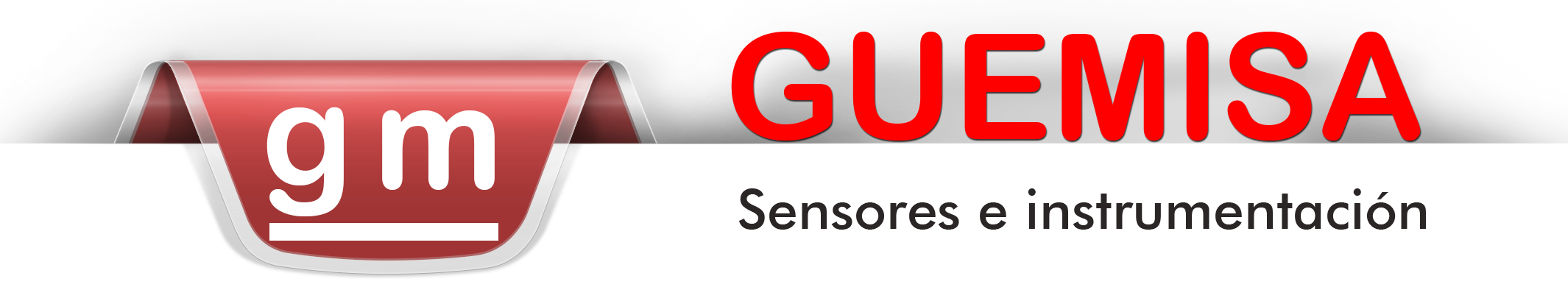

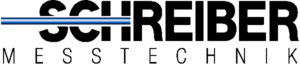

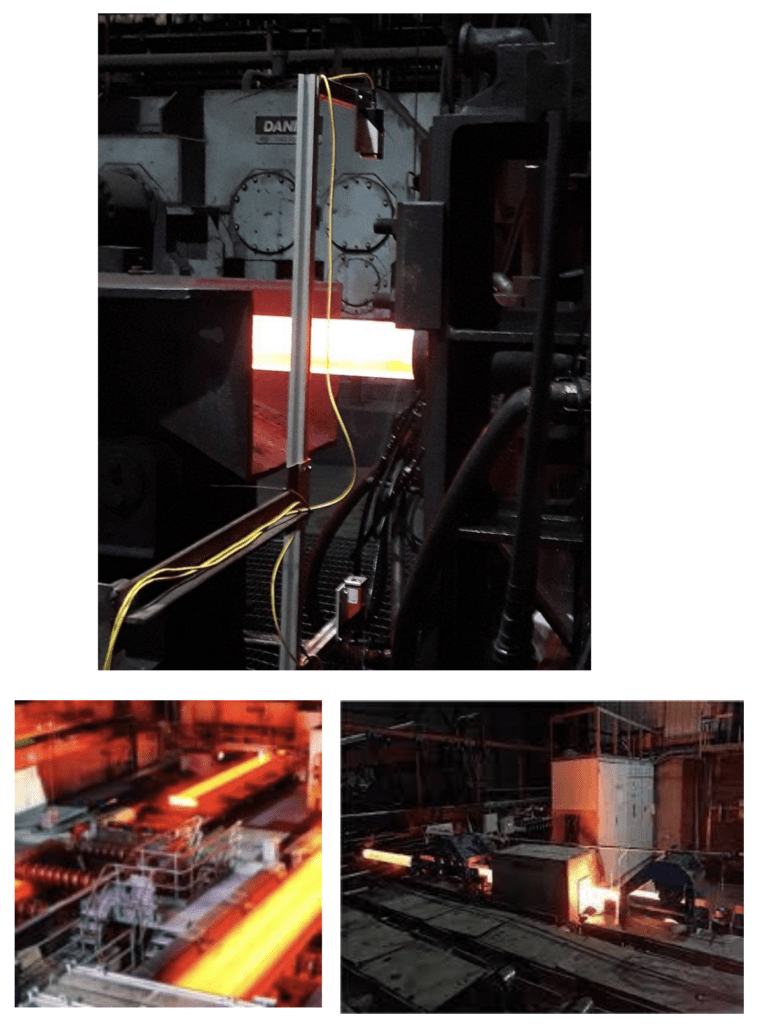

Another solution for monitoring continuous casting furnaces is the diameter control after leaving the extruder to measure the diameter of steel tubes and bars. Thanks to the measurement stability of our sensors up to 60ºC. The solution for the customer was very satisfactory. In some cases where the temperature was 120ºC, protective housings for the sensor were designed with Peltier effect cooling to withstand high temperatures.

Customer benefits

• Easy installation thanks to visible laser beam.

• Easy setup thanks to free software.

• Operates stably over a very wide temperature range from -40 to +60 °C • Measuring ranges up to 500 m on reflective film or 100 m on natural surfaces. • Accuracy ± 1 mm.

• Repeatability ± 0.3 mm.

• Maintenance-free operation.

Dimetix sensors offer numerous features, which are integrated into each and every device as standard, including, among others, various interfaces such as SSI, RS-422/485, RS-232 and 2 digital outputs. Optionally, industrial Ethernet interfaces are also available: PROFINET, EtherNET/IP and EtherCAT. In addition, all devices have IP65 protection and a weight of 500gr thanks to their aluminium housing.

We are proud of the Swiss precision of 1 millimetre at distances up to 500 metres, even in the most extreme conditions, depending on the model purchased.

We calibrate and test the 100% sensors and electronics one by one. We place the sensors in a climate cabinet with temperatures from -40ºC to +70ºC to calibrate the thermal drift with 2,000 readings per sensor and then we do the longitudinal calibration on our 40m long mobile calibration bench and finally according to the sensor model with a fixed point at 500m.

For more information, please contact us and we will inform you which models may best suit your needs.